World’s First Thorium Molten Salt Nuclear Reactor Goes Live: Understanding China’s Breakthrough in Advanced Nuclear Energy

China’s launch of the first operational thorium molten salt reactor marks a paradigm shift in clean energy by demonstrating continuous, high-temperature, low-pressure nuclear power generation. Readers will learn how molten salt carries thorium fuel, why this design enhances safety and efficiency, how waste volumes shrink dramatically, and what China’s Gobi Desert facility reveals about advanced reactor commercialization. We will explore the reactor’s core components, passive safety systems, waste-reduction mechanisms, economic and environmental benefits, as well as historical lessons and remaining hurdles. This overview positions thorium molten salt technology at the forefront of sustainable nuclear innovation.

What is a Thorium Molten Salt Reactor and How Does It Work?

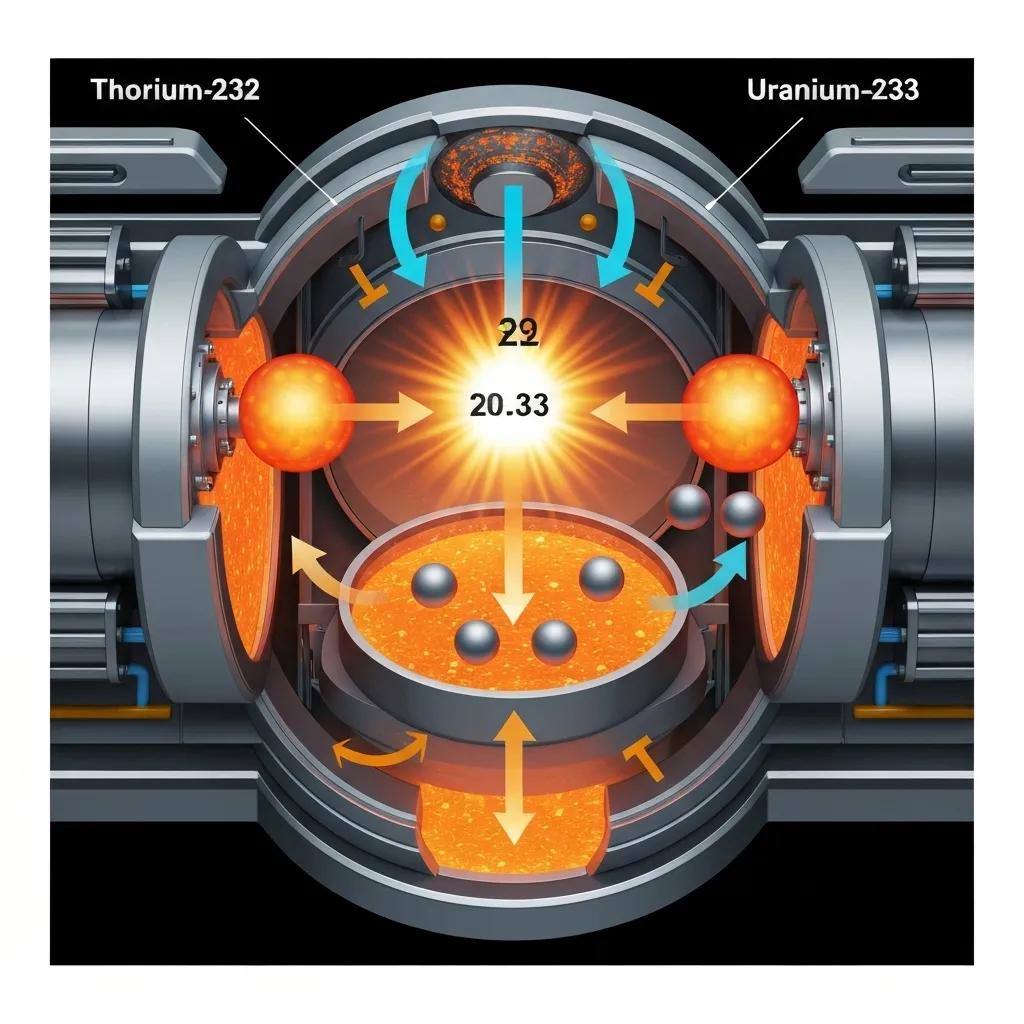

A thorium molten salt reactor is a nuclear fission system in which thorium-232 is dissolved or suspended in fluoride-based molten salt that simultaneously serves as fuel carrier and coolant, enabling continuous energy extraction at high temperatures and atmospheric pressure. In this design, thorium is converted to fissile uranium-233 within the circulating salt, where fission reactions release heat transferred through heat exchangers to drive electricity-producing turbines.

What are the key components of a thorium molten salt reactor?

A thorium molten salt reactor relies on four primary subsystems that integrate to sustain fission and heat removal.

- Fuel Salt Circuit – A mixture of lithium fluoride, beryllium fluoride, and thorium-uranium fluorides circulates through the core to sustain the breeding and fission cycle.

- Graphite Moderator – Hexagonal graphite blocks slow fast neutrons to thermal energies, enhancing the capture cross-section of thorium and uranium isotopes.

- Heat Exchanger Assembly – Intermediate salt loops transfer core heat to secondary coolant loops, isolating radioactive circuits from power-generation equipment.

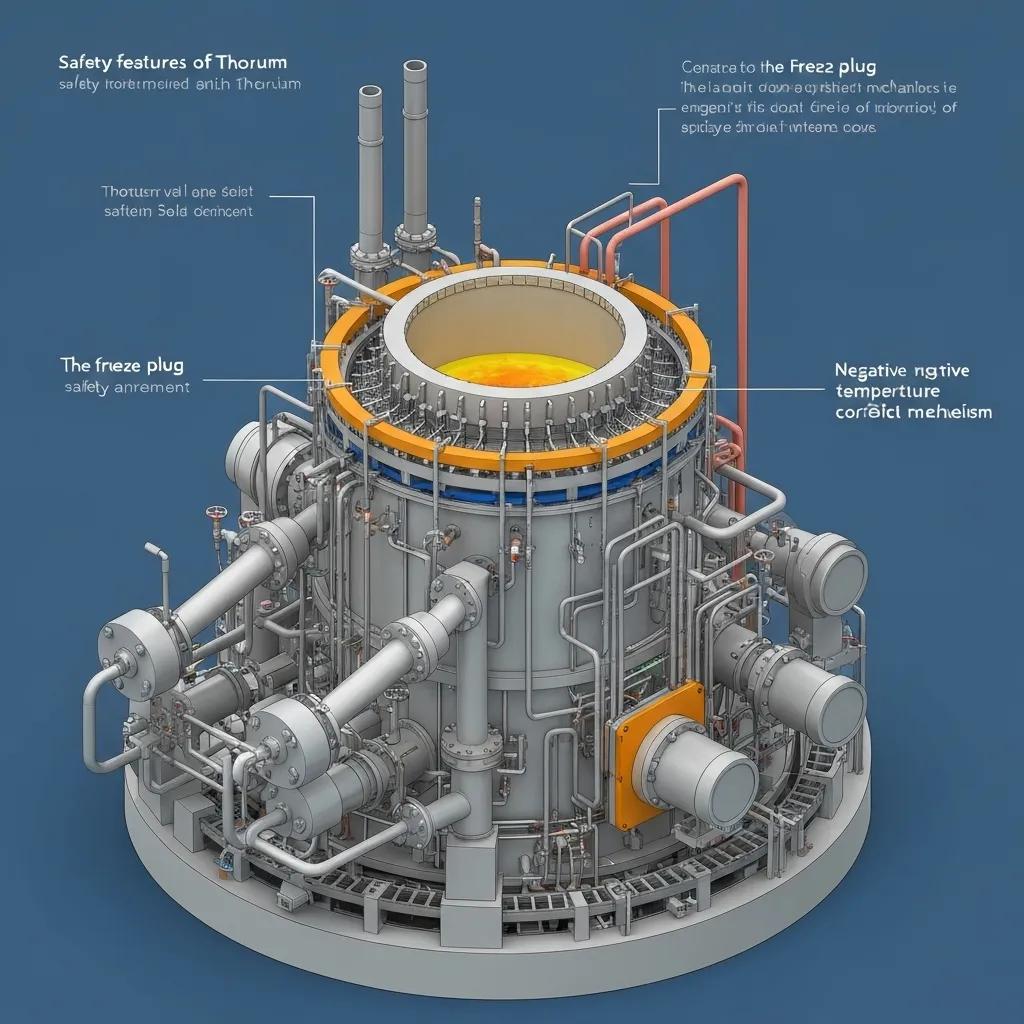

- Freeze Plug and Drain Tank – A passive safety mechanism melts a low-temperature plug upon overheating, draining fuel salt into subcritical storage to halt fission.

These components work in concert to maintain criticality while offering intrinsic safety and continuous refueling capabilities that drive advanced reactor performance.

How does molten salt function as fuel and coolant in these reactors?

Molten salt serves dual roles by dissolving fissile and fertile material for direct neutron interaction and by absorbing thermal energy with minimal temperature rise. Its high boiling point (exceeding 1400 °C) and low vapor pressure at operating temperatures (650 °C–750 °C) eliminate high-pressure systems, reducing mechanical stress and leakage risk. A secondary salt loop then transports heat to turbine generators, decoupling radioactive fluid from power conversion and improving maintenance access.

By combining fuel and coolant functions, molten salt enables uniform temperature distribution, high thermal inertia, and efficient heat transfer under near-atmospheric conditions, which in turn supports the reactor’s inherent safety.

How does nuclear fission occur in thorium molten salt reactors?

In these reactors, thorium-232 captures a neutron to become thorium-233, which undergoes two beta decays to form fissile uranium-233. Uranium-233 nuclei then absorb thermal neutrons and split into lighter isotopes, releasing about 200 MeV of energy, additional neutrons, and fission products. The newly liberated neutrons sustain a breeding-fission cycle by converting more thorium to uranium-233. Continuous circulation of the salt enables online refueling: adding thorium while extracting fission products to maintain reactor criticality.

This integrated breeding and fission mechanism enhances fuel utilization and supports long-duration operations without full shutdowns, demonstrating why molten salt reactors hold promise for advanced nuclear energy.

Why is Thorium Nuclear Power Considered Safer and More Efficient?

Thorium molten salt reactors improve reactor safety by operating at low pressure, using chemically inert salts, and incorporating passive shutdown systems, while efficiency gains arise from superior fuel utilization and high thermal output.

What inherent safety features do thorium molten salt reactors have?

Thorium molten salt reactors incorporate passive safety mechanisms that eliminate reliance on active cooling systems.

- A freeze plug melts under overheating, draining salt into subcritical cooled storage.

- A negative temperature coefficient ensures that rising temperature reduces reactivity automatically.

- The already-molten fuel eliminates solid-core meltdown risk by design.

How does thorium fuel improve reactor efficiency compared to uranium?

Thorium breeding yields uranium-233 with a higher neutron yield per fission than uranium-235, boosting conversion ratios above 1.0. Enhanced breeding cycles achieve up to 99 % resource utilization, compared with 1–2 % in conventional uranium reactors. This level of efficiency reduces fuel mining, enrichment, and long-term waste management costs by maximizing the energy extracted from each ton of thorium feedstock.

How do molten salt reactors operate at low pressure and high temperature safely?

Molten salt reactors maintain system pressures near atmospheric levels because the salts’ high boiling points prevent phase changes at operating temperatures (650 °C–750 °C). Low pressure reduces the risk of large-scale leaks and mechanical failures in pressure vessels and piping. By maintaining a single-phase fluid under these conditions, reactor designers achieve high thermal efficiency for power generation while ensuring structural resilience and minimized accident scenarios.

How Does Thorium Molten Salt Reactor Technology Reduce Nuclear Waste?

Molten salt reactors using thorium produce waste streams with lower volume and shorter radiotoxicity lifetimes, simplifying disposal and reducing environmental impact.

What types of nuclear waste are produced by thorium reactors?

Thorium molten salt reactors generate three main categories of waste:

- Fission Products – Isotopes such as cesium-137 and strontium-90 with half-lives up to 30 years.

- Activation Products – Neutron-activated structural materials (e.g., steel and graphite) with moderate half-lives.

- Minor Actinides – Trace amounts of neptunium and americium formed through neutron capture.

Compared with uranium reactors, the volume of long-lived transuranics is significantly lower, and the dominant fission products decay to safe levels within a few centuries.

How does thorium fuel cycle shorten radioactive waste half-life?

The thorium cycle shifts the waste profile toward shorter-lived fission fragments by minimizing plutonium and other transuranic production. Most actinides in a thorium reactor decay below hazardous thresholds within 300–500 years, whereas uranium-plutonium waste requires geological isolation for tens of thousands of years. By converting thorium to uranium-233 on-site and extracting fission products continuously, molten salt designs maintain a cleaner waste stream.

What are the strategies for managing and disposing of thorium reactor waste?

Managing thorium reactor waste combines on-site reprocessing, transmutation, and geological disposal.

- Reprocessing separates fission products and recycles fertile thorium and fissile uranium-233.

- Transmutation uses neutron flux in dedicated reactors to convert minor actinides into shorter-lived isotopes.

- Geological Repositories finalize disposal of residual waste in stable rock formations, with substantially reduced heat load and radiotoxicity.

This integrated approach reduces repository footprint and long-term monitoring obligations while maximizing resource recovery from spent salt.

What Milestones Has China Achieved with the World’s First Operational Thorium Molten Salt Reactor?

China’s experimental TMSR-LF1 in the Gobi Desert has set global milestones by reaching full power, demonstrating continuous refueling, and charting a path toward larger demonstration reactors.

Where is China’s thorium molten salt reactor located and what is its significance?

The TMSR-LF1 facility is situated in the resource-rich Gobi Desert near Golmud. Its remote location provided ample space for testing high-temperature molten salt operations and logistic support for uranium-233 generation. By achieving sustained criticality, the site underscores China’s commitment to deploying low-carbon advanced reactors and establishes an international benchmark for thorium research.

How did China achieve continuous refueling without shutdown?

Engineers implemented on-line salt purification and feed-injection systems that remove fission products while adding fresh thorium-lithium fluoride salt. By routing fuel loops through external processing modules, the reactor maintained criticality during salt exchanges. This technical breakthrough validates continuous operation, improves capacity factors, and reduces downtime traditionally required for refueling.

What are China’s future plans for thorium molten salt reactor development?

Building on TMSR-LF1, China aims to construct a 10 MWe demonstration reactor by 2030, followed by scalable commercial units exceeding 100 MWe. Partnerships with industry leaders will focus on modular designs for grid integration, industrial heat applications, and hydrogen production. These goals reinforce China’s leadership in next-generation nuclear energy and global clean-power deployment.

What Are the Economic and Environmental Benefits of Thorium Molten Salt Reactors?

Thorium molten salt reactors tap abundant resources, cut fuel and waste costs, and deliver low-carbon electricity while unlocking versatile industrial heat services.

How abundant is thorium compared to uranium and why does it matter?

How do thorium reactors contribute to clean energy and decarbonization?

Thorium molten salt reactors produce virtually zero greenhouse gas emissions during operation and require smaller fuel inventories, which reduces mining-related CO₂ output. By integrating high-temperature heat, they support process electrification in steelmaking, petrochemicals, and district heating, further displacing fossil fuels across industrial sectors.

What potential non-electrical uses exist for molten salt reactors?

Molten salt reactors can generate process heat and hydrogen through high-temperature electrolysis or thermochemical cycles.

- Hydrogen Production promotes clean fuel for transportation and ammonia synthesis.

- Industrial Heat provides temperatures above 700 °C for cement, glass, and chemical manufacturing.

- Desalination uses waste heat for efficient freshwater production in arid regions.

What Challenges and Barriers Remain for Thorium Molten Salt Reactor Commercialization?

While demonstrating remarkable promise, thorium molten salt reactors face material, regulatory, and economic hurdles that must be addressed before widescale deployment.

What material science challenges affect molten salt reactor durability?

High-temperature fluoride salts corrode nickel-based alloys and graphite moderators over time. Researchers are developing advanced corrosion-resistant alloys and ceramic coatings to extend component lifetimes beyond 30 years. Material qualification under intense neutron flux remains critical for validating long-term performance and reducing maintenance intervals.

How do regulatory frameworks impact thorium reactor deployment?

Existing nuclear regulations focus on light-water reactor safety parameters, requiring adaptation of licensing processes for molten salt designs. Regulators need new standards for salt chemistry monitoring, passive safety validation, and waste classification. Harmonizing international guidelines through agencies like the IAEA will streamline approvals and foster cross-border collaboration.

What economic and investment hurdles must be overcome?

Initial capital costs for advanced reactors remain high compared with established fossil or light-water nuclear plants. Cost reductions rely on modular factory fabrication, supply-chain maturation, and standardization. Private investment and government incentives play a vital role in derisking projects and accelerating first-of-a-kind demonstrations to unlock economies of scale.

How Does the History of Molten Salt Reactor Development Inform Today’s Thorium Reactor Advances?

The lineage of molten salt research at Oak Ridge National Laboratory laid the scientific foundation for modern thorium-based designs, illustrating both early promise and factors that stalled past programs.

What was the role of Oak Ridge National Laboratory in early MSR research?

Between 1954 and 1969, Oak Ridge scientists conducted the Molten Salt Reactor Experiment (MSRE) and Aircraft Reactor Experiment (ARE), demonstrating molten fluoride salts as viable reactor fluids. They validated passive safety features, online fuel processing, and graphite moderation, proving key principles that underpin today’s thorium molten salt concepts.

Why did the US abandon thorium reactor programs historically?

Policy shifts toward uranium-plutonium fast breeder reactors, combined with budget constraints and geopolitical priorities, diverted funding away from MSR efforts. Technical challenges in corrosion control and regulatory uncertainty further dampened momentum, causing the US to end MSR research despite its early successes.

How is global research collaboration shaping the future of thorium reactors?

International consortia like the Generation IV International Forum and IAEA coordinate material testing, safety analysis, and licensing frameworks for molten salt systems. Collaborative projects in Europe, India, and China share experimental data, alloy development, and simulation tools, accelerating commercialization timelines through collective expertise.

Thorium molten salt reactors now stand poised to fulfill their decades-old promise of clean, efficient, and inherently safe nuclear power, drawing on historical breakthroughs and modern innovation to chart a sustainable energy future. This milestone in China’s Gobi Desert demonstrates the feasibility of continuous refueling and passive safety at scale. By leveraging thorium’s abundance and reducing waste half-lives dramatically, molten salt reactors can support clean energy and industrial processes with minimal environmental impact. Overcoming remaining material, regulatory, and economic barriers will require coordinated research, policy adaptation, and investment. Continued international collaboration promises to deliver scalable thorium reactor fleets that strengthen energy security and decarbonize heavy industries worldwide.