World’s First Thorium Molten Salt Nuclear Reactor Goes Live

World’s First Thorium Molten Salt Nuclear Reactor Goes Live: Exploring China’s Breakthrough in Advanced Clean Energy Innovation

China has activated the world’s first operational thorium molten salt nuclear reactor, demonstrating a pivotal advance in clean energy research and innovation. This milestone promises enhanced safety, reduced nuclear waste, abundant fuel security, and higher efficiency for next-generation power generation. In this article, we will explore the technology behind thorium molten salt reactors (TMSRs), unpack their safety features, examine environmental and economic benefits, review China’s TMSR-LF1 achievement, address development challenges, and assess how TMSRs fit into the global clean energy transition.

What Is a Thorium Molten Salt Reactor and How Does It Work?

A thorium molten salt reactor (TMSR) is a Generation IV nuclear fission system that uses liquid fluoride salts both as a fuel carrier and coolant, enabling continuous operation and enhanced safety. By dissolving fertile thorium (Th-232) and fissile uranium-233 in molten salt at atmospheric pressure, TMSRs achieve efficient energy conversion and on-line reprocessing for cleaner power. For example, China’s TMSR-LF1 prototype in the Gobi Desert operates at 600 °C, producing stable electricity with minimal long-lived waste. Understanding molten salt reactor history sets the stage for exploring the thorium fuel cycle and salt chemistry in TMSRs.

What defines Molten Salt Reactor Technology and its history?

Molten salt reactor technology originated in the 1950s with the Oak Ridge MSRE project aimed at testing liquid fluoride salts in a critical system. These reactors leverage a graphite moderator and molten fluoride salts—typically lithium fluoride (LiF) and beryllium fluoride (BeF₂)—to sustain a controlled fission chain reaction while circulating the fluid fuel through heat exchangers. Continuous operation trials in the MSRE demonstrated stable criticality and corrosion management, laying the groundwork for modern TMSRs that now integrate thorium fuel cycles and advanced materials.

Molten Salt Reactor Technology and History

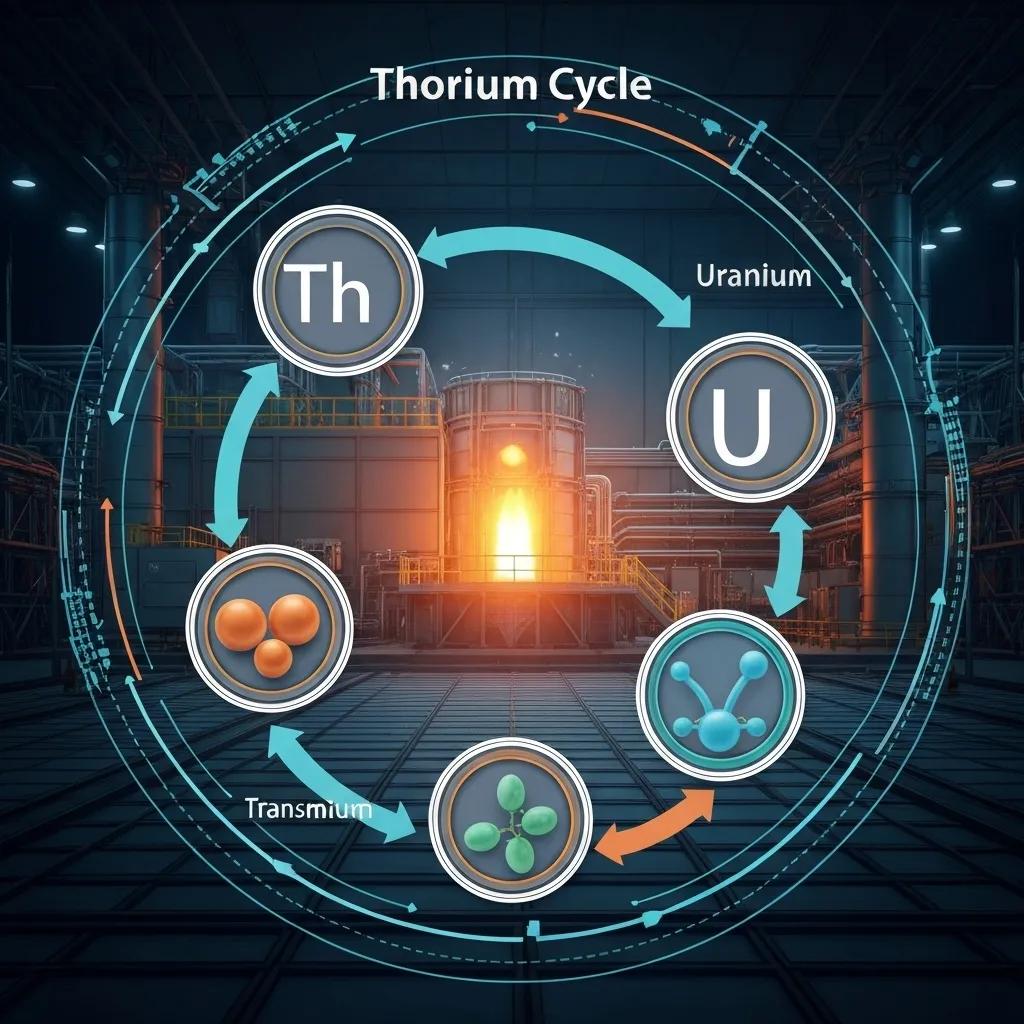

How does the thorium fuel cycle operate in TMSRs?

The thorium fuel cycle operates by transmuting thorium-232 into fissile uranium-233 via neutron capture:

- Thorium-232 absorbs a neutron → becomes thorium-233

- Thorium-233 β-decays → protactinium-233

- Protactinium-233 β-decays → uranium-233, which fissions to release energy

This mechanism supports continuous refueling: fertile thorium is added, fission products are removed, and uranium-233 regenerates, sustaining a long-term power output. The inherent breeding process reduces fuel handling complexity and minimizes the need for enriched uranium.

What role does molten salt play as fuel carrier and coolant?

Molten salt serves dual functions in TMSRs by dissolving fissile and fertile materials as fuel and by transferring heat at high temperatures. These salts remain liquid between 500 °C and 700 °C, allow low-pressure operation, and provide strong heat capacity for efficient thermal exchange.

This combination of salt chemistry and fluid mechanics enables stable heat removal and continuous reprocessing, driving reactor efficiency and safety enhancements for advanced clean energy systems.

What Are the Key Safety Features of Thorium Molten Salt Reactors?

Thorium molten salt reactors incorporate passive safety systems, low-pressure operation, and materials with negative temperature coefficients to prevent accidents and eliminate meltdown risks. These design elements collectively promote inherent reactor stability and rapid shutdown in emergency conditions.

How do passive safety mechanisms like the freeze plug prevent meltdowns?

A freeze plug is a passive safety device consisting of a salt-filled drain line kept solid by active cooling. In overheat scenarios, the plug melts, allowing molten salt to drain into a subcritical, passively cooled dump tank where fission stops. This mechanism requires no operator action or external power, guaranteeing automatic reactor shutdown and preserving structural integrity under loss-of-coolant events.

Why does atmospheric pressure operation enhance reactor safety?

Operating at atmospheric pressure eliminates high-pressure hazards associated with water-cooled reactors. Without pressurized vessels and steam generators, TMSRs avoid catastrophic ruptures and reduce engineering complexity. The low-pressure environment simplifies containment design, lowers construction costs, and enhances reactor resilience against pressure-related failures.

What inherent design elements reduce nuclear accident risks?

Three core design features further mitigate accident potential:

- Negative Temperature Coefficient ensures that rising temperatures decrease reactivity.

- Single-phase fluid fuel prevents phase transitions that could block coolant channels.

- Continuous online reprocessing removes volatile fission products before they accumulate.

These elements work together to maintain stable power output, automatically counteract reactivity excursions, and minimize radioactive release under off-normal conditions.

How Do Thorium Molten Salt Reactors Reduce Nuclear Waste and Environmental Impact?

Thorium molten salt reactors dramatically cut the volume and longevity of nuclear waste by achieving high burn-up rates, enabling online fuel recycling, and producing shorter-lived radioactive isotopes. This cleaner footprint supports sustainable nuclear energy adoption.

In what ways does online reprocessing minimize long-lived radioactive waste?

Online reprocessing continuously extracts fission products—especially rare earths and noble metals—directly from the circulating salt. By maintaining optimal fuel composition, TMSRs achieve burn-up rates exceeding 95 %, leaving significantly fewer long-lived actinides in the tail.

Thorium Fuel Cycle and Waste Reduction

How does thorium fuel cycle contribute to cleaner nuclear energy?

The thorium cycle inherently generates fewer transuranic elements because fertile Th-232 produces U-233 with limited higher-actinide formation. With shorter-half-life fission products and minimal plutonium production, spent salt exhibits a reduced hazard period compared to uranium-fueled reactors.

What environmental advantages do TMSRs offer compared to traditional reactors?

Why Is Thorium Fuel Abundant and What Are Its Advantages Over Uranium?

Thorium is approximately three times more abundant in Earth’s crust than uranium, offering a secure and sustainable fuel supply for centuries. Its natural distribution and high energy density make thorium an attractive alternative for long-term clean energy planning.

How abundant is thorium compared to uranium globally?

Thorium resources are estimated at 6 million tonnes versus roughly 2 million tonnes of economically recoverable uranium. Major thorium deposits exist in India, Australia, and the United States, ensuring diverse supply chains and energy independence.

What makes thorium a secure and sustainable nuclear fuel?

Thorium’s widespread availability, low potential for weaponization, and efficient breeding into U-233 foster energy security. The thorium cycle reduces proliferation risks by avoiding direct plutonium creation and leverages natural ore for high-density energy output.

How does thorium’s role in TMSRs support long-term clean energy?

In molten salt reactors, thorium provides a continuous stream of fissile material through in-situ conversion and online reprocessing. This capability extends fuel utilization beyond conventional reactor lifetimes and underpins multi-decade power deployments with minimal refueling logistics.

What Are the Economic and Efficiency Benefits of Thorium Molten Salt Reactors?

Thorium molten salt reactors deliver higher thermal efficiency, lower capital and operational costs, and versatile heat applications that support electricity, hydrogen, and process heat markets.

How do higher operating temperatures improve reactor efficiency?

Operating at 600 – 700 °C versus ~300 °C in pressurized water reactors increases Carnot efficiency from ~33 % to ~45 %. This temperature rise reduces fuel usage per megawatt-hour and enhances economic returns on investment.

What are the projected capital and operational cost advantages?

TMSRs utilize simpler steel vessels at atmospheric pressure, eliminate heavy steam generators, and reduce containment requirements. Combined with modular construction and reduced fuel handling, these factors can cut overnight capital costs by 20–30 % and lower operational expenses through extended refueling intervals.

Which industrial applications can benefit from TMSR technology?

- Electricity generation with high-temperature steam for grid stability.

- Hydrogen production via thermochemical cycles at 600 °C+.

- District heating and industrial process heat for petrochemicals and desalination.

How Has China Achieved the World’s First Operational Thorium Molten Salt Reactor?

China’s TMSR-LF1 project in the Gobi Desert marks the first continuous thorium molten salt reactor to reach criticality, full power, and on-line refueling, showcasing a combination of advanced materials, regulatory support, and institutional collaboration.

What is the significance of the TMSR-LF1 project in the Gobi Desert?

The Gansu Province prototype demonstrates continuous operation in a remote desert climate, validating passive cooling and salt chemistry under extreme conditions. This testbed accelerates commercialization pathways for larger-scale thorium MSR plants.

How was continuous refueling without shutdown accomplished?

Engineers implemented a dual-loop salt circulation system with hot-side on-line separators that extract fission products while replenishing thorium feedstock. This arrangement maintains reactor criticality and power output without interrupting operations, a first in nuclear history.

Who are the key organizations and scientists behind this achievement?

The Shanghai Institute of Applied Physics (SINAP) led development in partnership with national research labs. Chief scientist Xu Hongjie guided the reactor design, while materials specialists and regulatory bodies collaborated to meet international safety standards and secure operational licensing.

What Challenges Do Thorium Molten Salt Reactors Face and How Are They Being Addressed?

Despite their promise, TMSRs confront materials corrosion, regulatory frameworks, and startup fuel supply issues that require coordinated research and policy development.

What materials and corrosion issues impact TMSR development?

High-temperature fluoride salts can corrode nickel alloys and graphite moderators over time. Advanced coatings, corrosion-resistant alloys, and impurity control through purge gas systems are under investigation to extend component lifetimes and ensure reliable operation.

How is regulatory uncertainty being managed for advanced reactors?

Governments and international agencies are drafting adaptable licensing frameworks that accommodate continuous reprocessing and non-traditional coolant media. Pilot programs and joint safety assessments foster shared best practices and streamline approval processes for novel reactor types.

What solutions exist for startup fuel and scaling production?

Initial U-233 or low-enriched uranium seeds are essential to initiate the thorium cycle. Partnerships among research institutes, fuel fabricators, and veteran reactor vendors are developing standardized seed assemblies and supply chains to support multiple prototype and commercial-scale TMSR deployments.

How Do Thorium Molten Salt Reactors Fit Into the Global Clean Energy Transition?

Thorium molten salt reactors complement renewables, decarbonize baseload grids, and integrate with hydrogen economies, positioning them as key elements in future low-carbon energy systems.

How do TMSRs compare with Small Modular Reactors and other Generation IV designs?

What role can TMSRs play in decarbonizing power grids and hydrogen production?

By supplying stable baseload electricity and high-temperature heat for electrolysis or thermochemical hydrogen cycles, TMSRs enable 24/7 clean energy output that compensates for renewable intermittency and drives industrial decarbonization in steel, ammonia, and transportation sectors.

What are the current investment and market trends driving advanced nuclear energy?

Private capital and government funds are flowing into advanced reactor startups, with global nuclear investment projected to exceed $1 trillion by 2035. Collaborative R&D centers, venture capital backers, and energy firms are prioritizing TMSRs alongside small modular and fast reactors to diversify clean energy portfolios and meet net-zero targets.

Thorium molten salt reactors represent a transformative leap in nuclear power, combining inherent safety, waste reduction, fuel abundance, and economic versatility. China’s TMSR-LF1 achievement underscores the maturity of this technology and paves the way for global deployment. Continued advances in materials science, regulatory frameworks, and fuel supply will accelerate commercial roll-out and integration with renewable systems. As nations strive for carbon neutrality, TMSRs stand poised to deliver reliable, emission-free electricity and process heat for decades to come.