Blue Origin Tests Reusable Engine for Lunar Lander

Blue Origin Tests Reusable BE-7 Engine for Lunar Lander: Innovations and Artemis V Mission Insights

Blue Origin’s BE-7 engine represents a breakthrough in reusable lunar propulsion, combining advanced cycle design, deep throttling, and 3D-printed components to deliver precise, repeatable landings on the Moon. This article unveils the BE-7’s core features, details how the Blue Moon lander is being developed for NASA’s Artemis V mission, explores Blue Origin’s strategic role in the Human Landing System, surveys real-world testing campaigns, and projects the long-term impact of reusable propulsion on lunar exploration. Readers will gain in-depth insight into engine technology, lander variants, contract significance, testing milestones, and future applications.

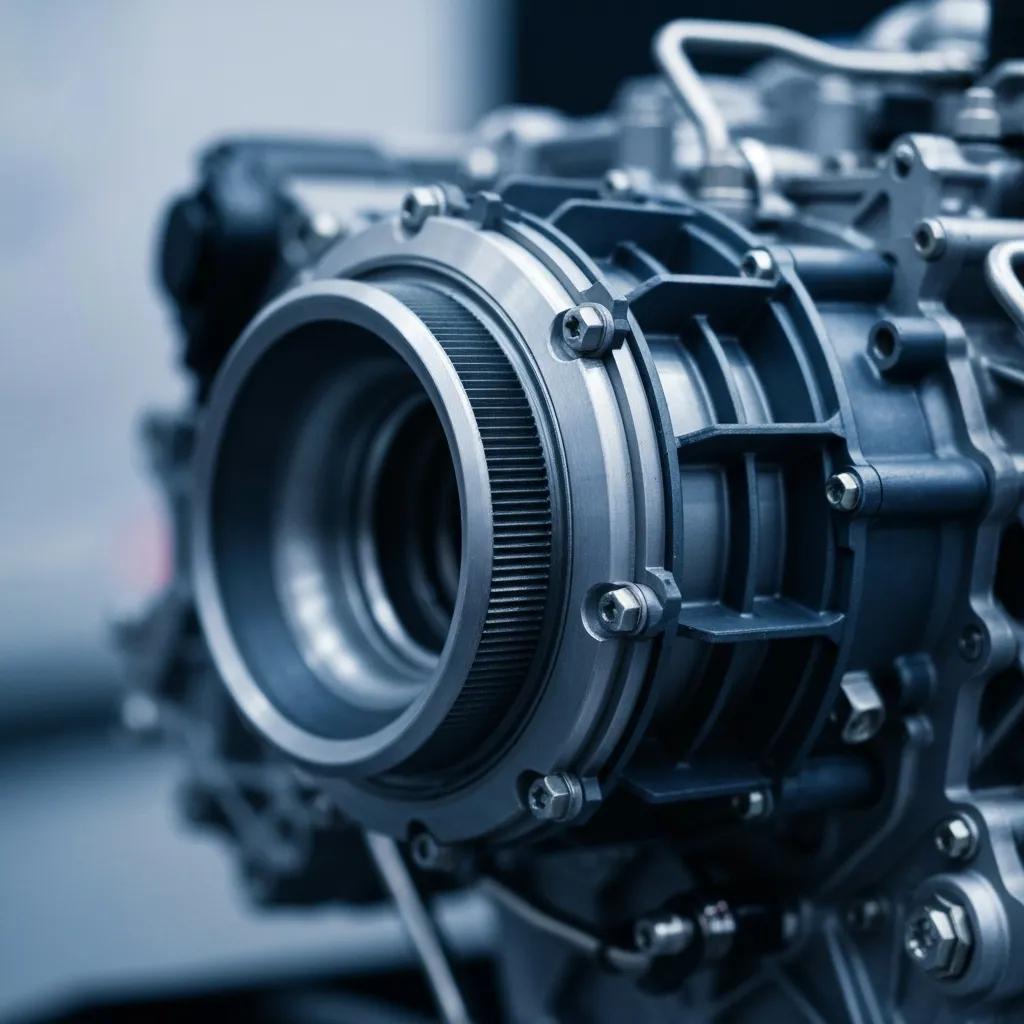

What Are the Key Features of Blue Origin’s BE-7 Reusable Lunar Engine?

The BE-7 engine is a dual-expander cycle liquid hydrogen/liquid oxygen rocket engine that integrates additive manufacturing and deep throttling to achieve 10,000 lbf of vacuum thrust with restart capability for sustainable lunar landings. By pairing lightweight, 3D-printed chambers with cryogenic propellants, BE-7 enhances specific impulse and operational flexibility for repeated descent and ascent missions.

Blue Origin, BE-7 | Blue Origin (2025)

Key features of the BE-7 engine include:

- Dual-expander cycle architecture that boosts thermal efficiency and performance

- Additively manufactured thrust chamber assemblies for rapid iteration and reduced mass

- Deep throttling range (20–100 percent thrust) enabling centimeter-scale landing precision

- Multiple restart capability supporting ascent from lunar surface

- Reusable design minimizing refurbishment between flights

These innovations lay the foundation for precision, cost-effective missions and set a new standard in lunar propulsion.

How Does the Dual Expander Cycle Enhance BE-7 Engine Performance?

The dual-expander cycle uses both hydrogen and oxygen to cool engine components before combustion, recovering heat energy to drive turbopumps and raising thermal efficiency. This mechanism increases specific impulse by up to 10 percent compared to single-expander designs, enabling longer burn durations and reduced propellant mass for lunar descent and ascent.

What Role Does Additive Manufacturing Play in BE-7 Engine Design?

Additive manufacturing allows complex cooling channels and thin-walled structures to be fabricated as a single part, reducing welds and potential failure points. This technique accelerates design iterations, cuts lead times by months, and lowers production costs while ensuring structural integrity under cryogenic conditions.

How Does Deep Throttling Enable Precision Lunar Landings?

Deep throttling provides fine-grained thrust control from 20 percent to full power, allowing the lander to hover and adjust descent trajectories in real time. By maintaining stable thrust at low levels, BE-7 supports centimeter-scale touchdown accuracy on uneven lunar terrain.

What Propellants Power the BE-7 Engine for Lunar Missions?

The BE-7 engine uses liquid hydrogen (LH2) as fuel and liquid oxygen (LOX) as the oxidizer, selected for their high specific impulse and clean combustion. Cryogenic management ensures efficient propellant storage and minimal boil-off during transit and surface operations, directly supporting mission sustainability.

These core capabilities of the BE-7 engine converge to deliver reliable, reusable lunar propulsion and prepare Blue Origin for Artemis V.

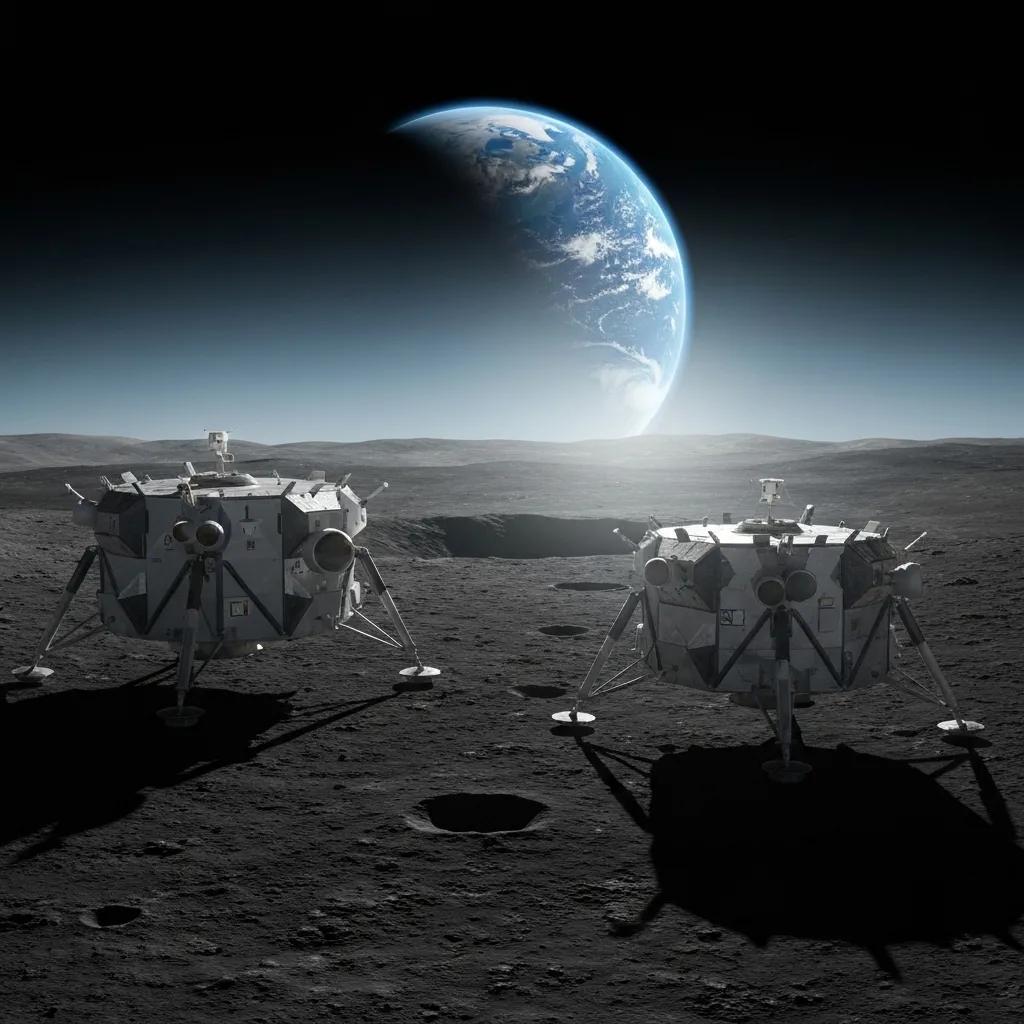

How Is Blue Origin Developing the Blue Moon Lunar Lander for Artemis V?

Blue Moon is Blue Origin’s family of lunar landers, designed in two variants—Mark 1 for cargo and Mark 2 for crew—that leverage the BE-7 engine to deliver precise payload deployment and astronaut return. By integrating BE-7’s deep throttling and restart features with modular structures, Blue Moon aims to support both robotic and crewed missions under NASA’s Artemis V contract.

Wikipedia, Blue Moon (spacecraft) (2025)

What Are the Differences Between Blue Moon Mark 1 and Mark 2 Variants?

Below is a comparison of the two Blue Moon variants highlighting their design focus and capabilities.

Mark 1 emphasizes automated cargo transfer, while Mark 2 integrates life-support systems and crew interfaces for human exploration.

How Does the BE-7 Engine Power the Blue Moon Lander?

BE-7 engines mount on the descent stage of both lander variants, providing controlled thrust for descent, hover, and ascent. Their deep throttling and restart capabilities enable Blue Moon to execute soft touchdowns and lift-off for return journeys, combining reliability with reuse potential and minimizing mission costs.

Who Are the Key Partners in Blue Moon’s National Team Collaboration?

- Lockheed Martin for avionics and landing guidance

- Draper for flight software and navigation algorithms

- Boeing for structural elements and integration

- Astrobotic for payload deployment systems

- Honeybee Robotics for surface mobility and ISRU equipment

This collaboration unites aerospace leaders to deliver a robust, mission-ready lander under the Artemis V program.

What Is Blue Origin’s Role in NASA’s Artemis Program and Human Landing System?

Blue Origin serves as NASA’s second Human Landing System provider under a $3.4 billion Artemis V contract, tasked with delivering astronauts safely to and from the lunar surface. By contributing BE-7-powered Blue Moon landers, Blue Origin enhances competition, redundancy, and technology diversity within the Artemis framework.

NASA, NASA Selects Blue Origin as Second Artemis Lunar Lander Provider (2023)

What Does the $3.4 Billion Artemis V Contract Mean for Blue Origin?

Securing the Artemis V contract validates Blue Origin’s reusable propulsion strategy and provides funding stability through mission development, extensive testing, and operational readiness. The contract underscores NASA’s confidence in private sector innovation to achieve sustainable lunar exploration goals.

How Will Blue Moon Support Artemis V Mission Objectives?

Blue Moon will execute an uncrewed demonstration followed by a crewed landing during Artemis V, transporting scientific instruments, cargo, and astronauts to the lunar south pole. Its precision landing enables exploration of high-priority sites and paves the way for long-duration surface activities and resource utilization.

How Does Blue Origin Compete and Collaborate Within the Artemis Program?

Blue Origin competes with other HLS providers by advancing reusability and precision while collaborating on interface standards, safety protocols, and mission integration. This balance of competition and cooperation drives technical excellence and mission assurance across the Artemis ecosystem.

Where and How Is Blue Origin Testing the BE-7 Engine for Lunar Missions?

Blue Origin conducts BE-7 engine testing in vacuum chambers and hot-fire stands to simulate lunar descent conditions, ensuring performance, reliability, and reusability metrics are met before flight certification. Integrated test programs validate thermal cycles, deep throttling, and restart sequences under representative pressures.

What Testing Facilities Are Used for BE-7 Engine Development?

- AFRL Edwards Air Force Base vacuum facility for altitude-simulation hot fires

- NASA Marshall Space Flight Center test stands for long-duration endurance runs

What Are the Key Milestones Achieved in BE-7 Engine Testing?

- Over 4,000 seconds cumulative hot-fire duration

- Successful deep-throttle firings at simulated lunar vacuum

- Multiple restart sequences demonstrating repeatable ignition

Cumulative data confirms BE-7’s readiness for integration with Blue Moon landers.

How Do Testing Processes Ensure Engine Reusability and Reliability?

Each BE-7 test campaign cycles through heat-soak, ignition, full-thrust, and shutdown phases, monitoring component wear, thermal stresses, and performance drift. Iterative adjustments informed by test data refine manufacturing tolerances and operational envelopes for multiple reuse cycles.

These rigorous protocols underpin BE-7’s reusable design and mission-critical reliability.

How Does Blue Origin’s Reusable Lunar Propulsion Technology Impact Future Space Exploration?

What Are the Advantages of Reusable Engines for Sustainable Lunar Missions?

- Cost Savings – Lower per-flight development and refurbishment expenses

- Rapid Turnaround – Faster mission cadence enabled by engine requalification

- Resource Efficiency – Reduced need for new hardware decreases launch mass demands

These benefits foster a sustainable lunar economy and continuous exploration.

How Could BE-7 Enable In-Situ Resource Utilization (ISRU) on the Moon?

BE-7’s restart and deep-throttle features allow landers to deliver ISRU processing units, power propellant production from lunar ice, and return processed cryogenics to orbital depots. Reusable engines support iterative ISRU demonstrations, accelerating local resource exploitation.

What Challenges Does Blue Origin Address in Lunar Propulsion Engineering?

- Cryogenic fluid management in vacuum and extreme thermal swings

- Plume-surface interactions that affect regolith and lander stability

- Thermal cycling fatigue in additively manufactured components

By solving these issues, BE-7 sets a template for reliable, long-duration lunar operations.

What Are the Technical Specifications and Innovations Behind the BE-7 Engine?

The BE-7 engine’s specifications highlight its balance of performance, reusability, and manufacturability, making it uniquely suited for lunar descent and ascent missions.

What Is the Thrust Capacity and Specific Impulse of the BE-7 Engine?

BE-7 produces 10,000 lbf of thrust in vacuum at a specific impulse of approximately 462 seconds, delivering the high efficiency and power necessary for both descent braking and ascent maneuvers on the lunar surface.

How Does the Engine’s Restart Capability Support Lunar Operations?

Multiple restart sequences allow the lander to perform initial descent, abort maneuvers, hover adjustments, and ascent burns using the same engine hardware, minimizing dry mass and simplifying mission profiles.

What Materials and Manufacturing Techniques Enhance BE-7 Durability?

BE-7 uses high-strength, cryogenic-grade alloys and additive-manufactured cooling passages to manage thermal loads. This approach ensures consistent performance across repeated thermal cycles and supports engine longevity.

How Does Blue Origin’s Testing and Development Strategy Support Artemis V Success?

Blue Origin’s phased testing and iterative design approach align closely with Artemis V milestones, ensuring that BE-7 engines and Blue Moon landers meet NASA’s performance, safety, and schedule requirements.

What Are the Phases of BE-7 Engine Testing and Validation?

- Thrust Chamber Assembly Tests – Validating material integrity under cryogenic flow

- Hot-Fire Vacuum Cell Runs – Simulating lunar pressure conditions

- Integrated Lander Stage Tests – Evaluating system-level performance with propellant tanks

How Is Data from Testing Used to Improve Engine Design?

Telemetry from sensors feeds into iterative updates of injector geometry, cooling channel paths, and turbopump settings. This data-driven refinement enhances combustion stability and extends reusable cycle life.

What Are the Next Steps in Blue Origin’s Lunar Lander Development?

Future work includes full-scale integrated tests with Blue Moon descent stages, final qualification runs under flight-like conditions, and coordination with NASA for Artemis V mission rehearsals and safety reviews.

By systematically validating each component and system integration step, Blue Origin’s development strategy ensures Artemis V success.

Blue Origin’s BE-7 engine and Blue Moon lander embody a new era of reusable lunar exploration. Through advanced cycle design, additive manufacturing, precise testing, and strategic NASA partnership, they establish a sustainable blueprint for continuous human presence on the Moon. As Artemis V approaches, the integration of BE-7’s reusable propulsion with Blue Moon’s flexible variants will shape the economics and feasibility of future deep-space missions, driving humanity toward a lasting off-Earth civilization.